1

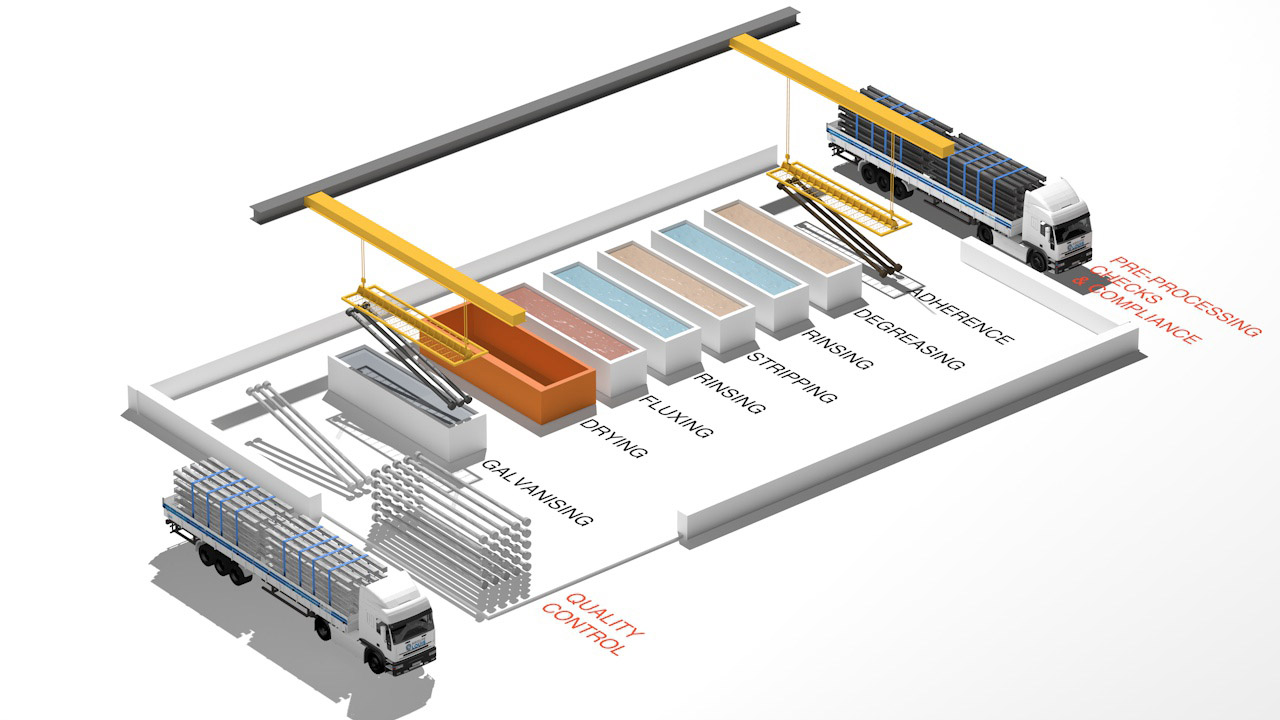

ORDER RECEIPT

Weighing the equipment and identifying references.

2

PRE-PROCESSING CHECKS & COMPLIANCE

Checking the products’ aptitude for galvanisation:

Surface condition, dimensions, design, drilling.

Quantitative checks in line with the customer’s purchase order.

Customer’s contact details in case of compliance-related measures.

3

ADHERENCE

Use of well-adapted tools according to the parts in question (round bars, chains, multiple hooks, etc.).

Optimising drilling positions.

4

DEGREASING

Its purpose is to remove all dirt and grease that would prevent surface iron oxides from dissolving.

5

RINSING

Rinsing occurs after he degreasing process so as not to pollute the following stages.

6

STRIPPING

Its purpose is to remove carbon deposits and other oxides on the steel’s surface.

Stripping is done using a hydrochloric acid solution diluted at room temperature, with added inhibiting agents to avoid the steel being attacked once the oxides have been removed.

7

RINSING

Another rinsing phase is launched after the stripping, to wash the iron salts and acid traces from the parts, as they may pollute the next stage.

8

FLUXING

This helps avoid the steel from re-oxidising before being plunged into the zinc bath. Decomposing the flow helps enhance the iron/zinc metal reaction when delving the part into the zinc bath.

9

DRYING

Drying is carried out in an oven, to avoid zinc projections when the part is plunged in.

10

GALVANISING

The parts are then plunged in a molten zinc bath at 450°C. Immersion times vary according to the loads, dimensions and thickness of the parts: 3 to 4 minutes for parts with simple shapes, 10 to 15 minutes for more massive products or large-size hollow entities.

11

COOLING & QUALITY CONTROL

Visual control upon removal from the zinc bath (aspect, distortion, etc.).

Testing thickness in comparison with a sample.

Delivery of a control report upon request, completed in line with the NF EN ISO 1461 standard.