Choice of steel prior to galvanisation

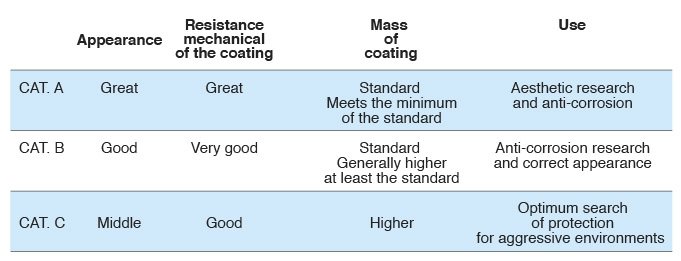

Specifications need to be imposed so these two elements are complied with. The NF A 35-503 standard “Steel for galvanisation using hot-dip immersion” defines three categories of steel, according to their guaranteed content of silicon and phosphorus. You can be guaranteed this content by asking the steel supplier for a product inspection document, as per the NF EN 10204 standard: the 3.1A receipt certificate.

NF EN ISO 1461: Hot-dip galvanisation coating on cast iron and steel finished products.

It defines the immersion galvanisation coating’s properties and characteristics, with testing methods able to control zinc thickness according to surface unit, as well as aspect and adherence, and other compliance criteria.

NF EN ISO 14713: Zinc coating. Guidelines and recommendations for protecting iron and steel against corrosion in constructions.

Serves as an addition to the precautions to be taken when designing parts, to obtain good-quality galvanised coatings, and specifies related techniques to be used after galvanisation.

NF A 35-503: Steel products. Requirements for the hot-dip galvanisation of steel items.

Sets out the chemical criteria to be met by steel soon to be galvanised via hot-dip immersion. It details three steel quality categories, suited for galvanisation.